The following is the second of a two-part series resulting from the collaboration between Amentum’s Product Support and Sustainment Engineering team, which supports the U.S. Navy’s Team Submarine, and Beast Code as they partner to leverage 3D models of weapons systems, discovering efficiency improvements for Navy life cycle sustainment activities.

by Dr. Lucas Marino and Dr. Kaitlynn Castelle

Digital twins provide one-to-one models at various levels of system recursion across relevant disciplines, allowing comprehensive, real-time representation of an asset’s supporting artifacts, products, and properties. They are often more than simply a collection of digital artifacts and data gathered during product development and use. Digital twins:

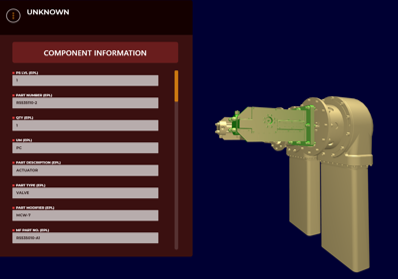

- Provide user-relevant views generated through digital thread connections to sources of 3D product model visualization and a configuration item’s associated data,

- Link to Logistics Supportability Analysis Record databases and underlying data sets, as well as to monitoring data, behavior models, and operational profiles,

- Support delivery of capabilities for displaying or simulating condition and behavior of the physical systems through models and data,

- Require management of underlying data and connectivity to authoritative data sources.

Digital threads provide the analytic framework to connect platform data models, associated logistics, technical and performance data, software, and functional support. A system, subsystem, or component’s digital thread:

- Provides configuration item traceability to each integrated logistics support (ILS) element depending on the application or use case. Acting as a fingerprint, it supports association of everything relevant to what it is, tracked through version-controlled records and historical logs to support development traceability, version history, and technical variance documentation across the lifecycle.

- Links digital twin capabilities of a product’s artifacts, allowing association of each configuration item to ILS element-relevant information. Examples include:

- supply support lists

- technical manuals

- general or special purpose drawings or diagrams (e.g. engineering schematics, interfacing diagrams, SUBSAFE mapping, fixture drawings)

- maintenance standards

- test procedures

- test pressure diagrams

- maintenance area details including connections, dimensions, zincs, linear feet of cable, conduit are all potential data elements in this respect.

Key Points for Implementation

Consider the following advice for remaining agile while delivering digital engineering capabilities to sustainment functions:

Remember Who the Customer Is: This is not negotiable; digital models are only useful to those who can use them. Operational users need easy-to-use tools to efficiently leverage digital twin technology with realistic simulations. Users need connections to logistics and technical data that are open, interoperable, adaptable, and available in the cloud and at the edge. Success requires a fully engaged team effort, from the technical product team down to the waterfront maintainers and operators.

Define the Relationships and Outcomes: Technology moves faster than acquisition and procurement rendering deeply decomposed requirements and specifications for these systems problematic. Agile product development provides the flexibility needed to explore innovations as teams work toward previously undefinable solutions and outcomes. Close relationships with highly engaged end-users benefit the long-term view of product data sustainment and development of new digital engineering capabilities to support future state planning yards and maintenance activities. A long-term view of product data sustainment should involve proactive experimentation and trial demonstration of data retrieval, access, transformation, consumption, management, integration, and sustainment across the enterprise.

All Digital Transformations are Unique: Realization and implementation of this technology can be challenged by cultural barriers and aversion to change, aging IT infrastructure, lack of talent, rigid contracts, and weak stakeholder collaboration and flexibility. However, you must remain focused on the unique value that your transformation provides. The convergence of unified disparate analysis tools, databases, and networks will ultimately improve life cycle management and enhance visibility and access for product support of major weapon systems.